Troubleshooting Guide for Chiller PCB & IGBT Output Module Failures

When a chiller system experiences issues, it’s important to understand the key components involved.

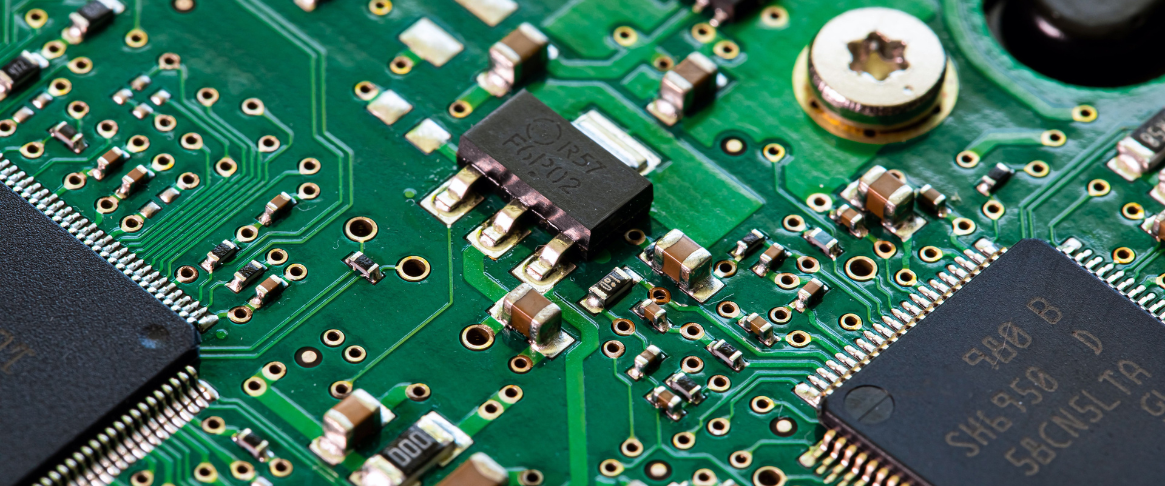

When a chiller system experiences issues, it’s important to understand the key components involved. Amongst them are PCB and IGBT output modules; these are some of the basic modules required for smooth application functions. But because there are so many causes for such failures, knowing how to identify and resolve them can save time and money in the aspect of maintenance.

The first step in troubleshooting is symptom evaluation. Such signs to suggest a damage in PCB or IGBT output module include if your chiller is not doing its cooling job right, or that would simply suggest a power failure in your entire system.

Check the PCB for any visible surface damage. Any burnt or damaged areas on the board are the first sign of failures due to overheating, voltage abuse, or due to faulty power supply sources. Check that everything is clean before checking for bad connections. Checking all the wiring will give hints about possible faulty connections that might have effects on the PCB functionality.

Do the same procedure while checking the IGBT output module, but first switch off the system to avoid causing further damage to the IGBT output module. IGBT modules are also prone to overheating and failure, as a result of too much current flowing through them. Always look for indications of damage or discoloration. Use a multimeter for testing the module because it easily detects short circuits or open circuits within the system.

Inadequate ventilation is among the greatest causes of much trouble in that the chiller runs in really poorly ventilated places. The air is not sufficient for heating to occur in excess, building up the temperature that damages the PCB and IGBT module. Do check for obstructions near the cooling fans and around the heat sinks.

Sometimes this issue can be a result of the power supply from the system. Make sure that the voltage supply for the PCB as well as IGBT modules is always within the defined range. These components would become damaged internally and boots when exposed to either high or low voltage conditions.

Because of routine maintenance, these components would tend to fail less frequently. Clean the system at regular intervals and replace already worn-out parts to keep the chiller running efficiently.

Should the troubleshooting steps be ineffective, seeking expert technical assistance may be necessary. Because of their advanced diagnostics and tailored solutions, they're arguably able to provide an optimum solution for the specific problem.

In summary, finding the problem in the chiller PCB & IGBT output module is a lot about a systematic approach to the work. It starts with inspection and goes through making certain that everything is operating as it should. Periodic maintenance would contribute to the lifetime extension of these critical parts, reducing the chances of an unexpected breakdown.

What's Your Reaction?